BrassChem

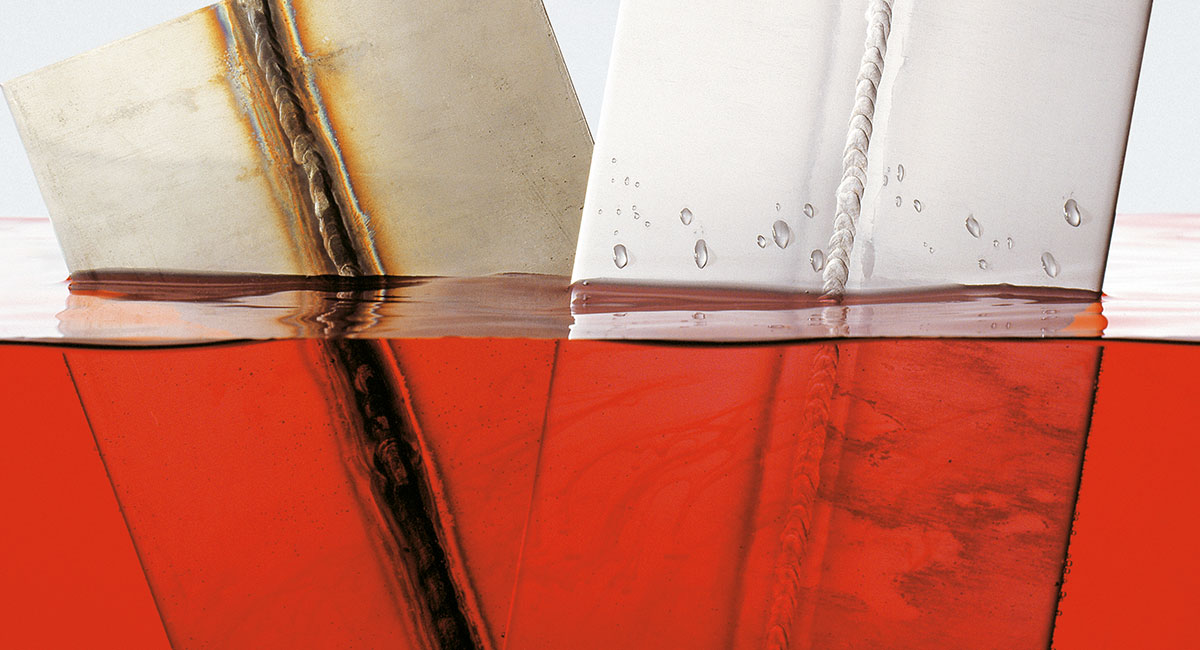

Chemical Polishing and Deburring Process for Brass

You need help? Of course!

You have further questions concerning our chemicals and how to use them?

Please do not hesitate to contact us. You can contact the responsible person of the division Poligrat Chemistry by the following telephone number:

+49 (89) 42778- 450

BrassChem is an innovative and highly efficient industrial process for the deburring, smoothening and brightening of brass. The degree of brightness achieved is strongly influenced by the concentration of lead in the alloy. A low lead content (MS 60/53) achieves best brightness.

When compared to conventional processes Brass-Chem is free from nitric and sulphuric acid and does not generate any toxic gases during the pro-cessing.

Wide processing window:

- short polishing time: 1 – 3 min.

- process temperature: 30 – 35 °C

- consistent results and process parameters right from the start up to a upper metal loading of ap-prox. 50 g metal/l

The highly effective smoothening working of Brass-Chem achieves an excellent brightness which is in most cases comparable to an electro polished sur-faces. The total metal removed, to achieve a similar brightness, is considerably than, other chemical brightening processes.

The low amount of metal removal to achieve opti-mum brightness significantly reduces the electrolyte consumption, when compared to conventional pro-cesses.

This leads to additional cost savings especially in respect to waste handling and disposal.

BrassChem is an immersion process. The parts to be treated can be processed either on jigs, in bas-kets or as bulk goods in rotary barrels.

The process sequence consists of two process steps:

- In the first process step (BrassChem V 100) the parts are cleaned free from oxidation.

- In a second process step (BrassChem G 100) the surface is smoothed and polished.

BrassChem and the rinse water from the process are acidic and contain the dissolved metal. They needs to be treated and disposed according to the statutory laws and regulations.

- very economics

- rapid gloss creation

- low processing temperature

- no creation of toxic processing gases

Supply

V 100 SK Single-use canister 10 kg ( 8.2 l)

G 100 SK 15 kg ( 9.9 l)

V 100 SK 35 kg (29.2 l)

G 100 SK Single-use canister 45 kg (29,7 l)

BrassChem V 100

Mixing for 100 l ready to use electrolyte:

DI water 87 l

hydrogen peroxide (35%) 2 l

sulphuric acid ( 96%) 9 l

BrassChem V 100 SK 2 l

BrassChem G 100

Mixing for 100 l ready to use electrolyte:

DI water 78 l

hydrogen peroxide (35%) 20 l

BrassChem G 100 SK 2 l