Corrosion occurs in a wide range of situations for a wide variety of reasons. It is usually an electrochemical process which requires moisture in the form of electrolytes and electric potential from local elements or external power. Passivated materials such as stainless steel, aluminium, titanium or zircon are protected by a resistant oxide layer (passive layer) on their surface against corrosion.

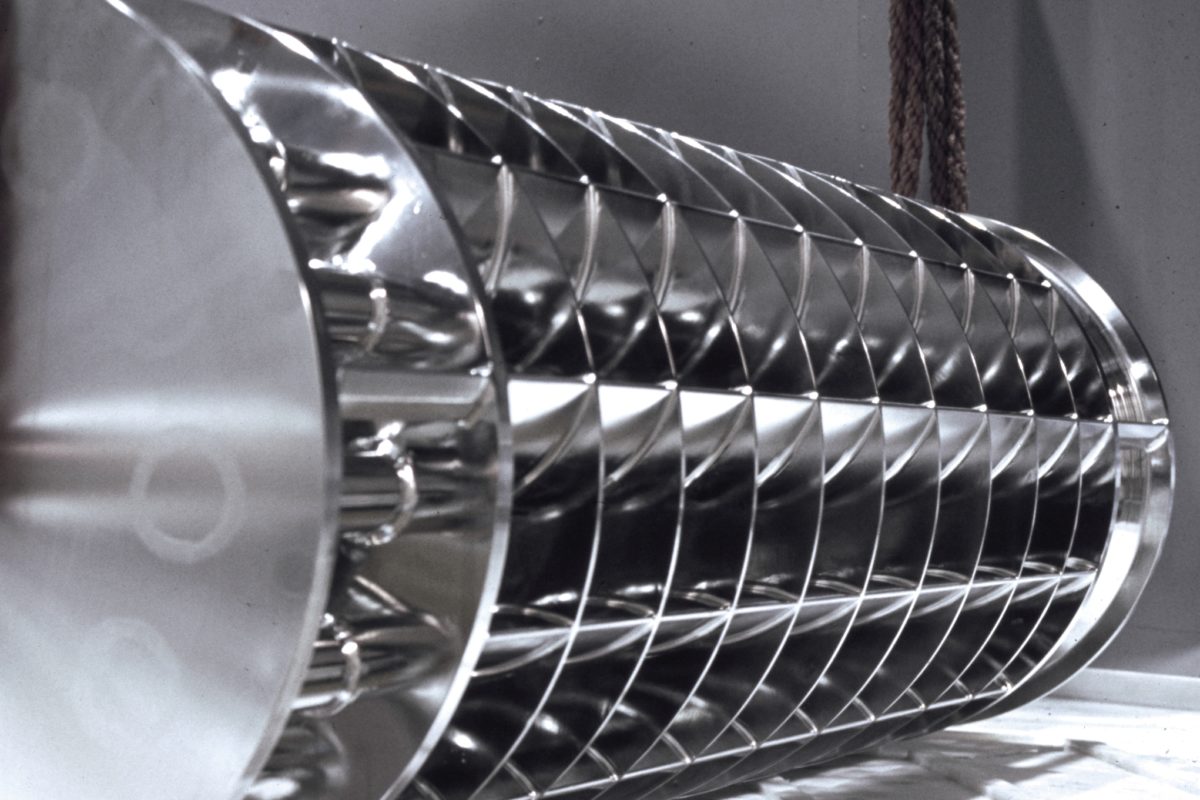

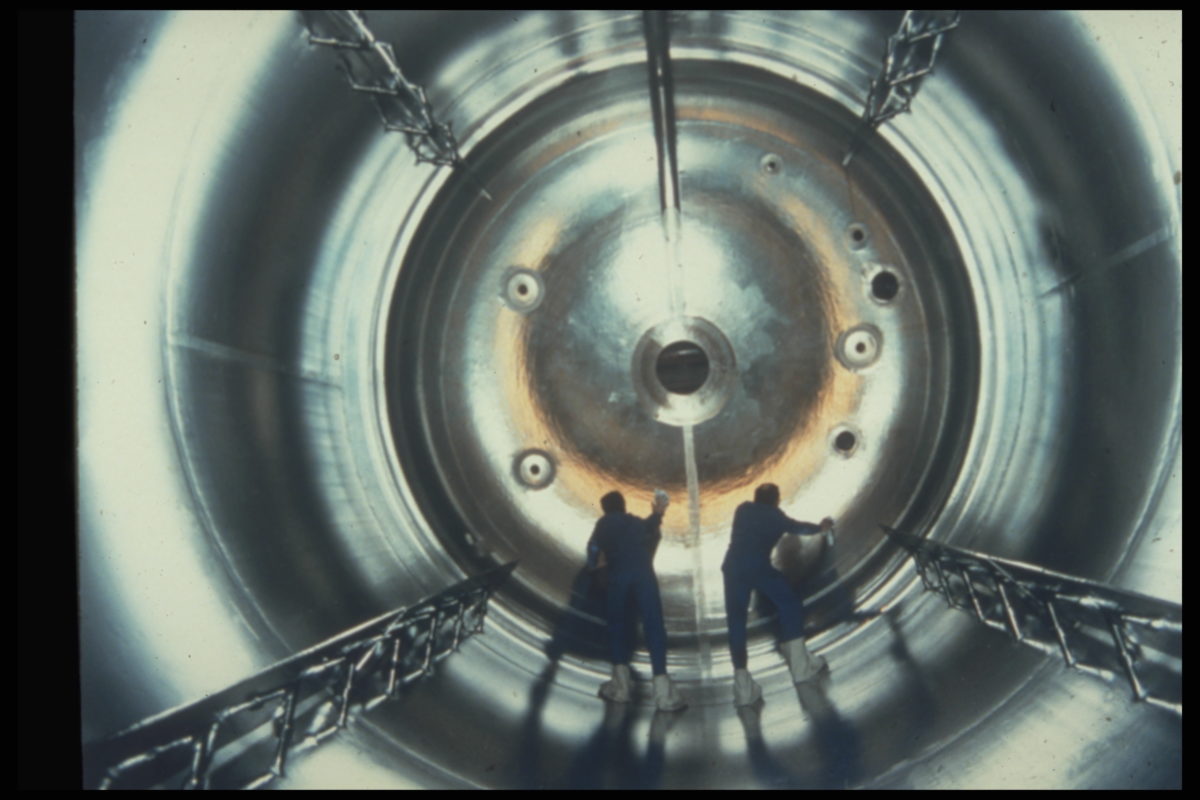

Added value through POLIGRAT processes

- Ideal conditions for the formation of homogenous and durable passive layers

- Optimal corrosion resistance

- Largely free of local elements

- Corrosion resistance of stainless steel is almost doubled

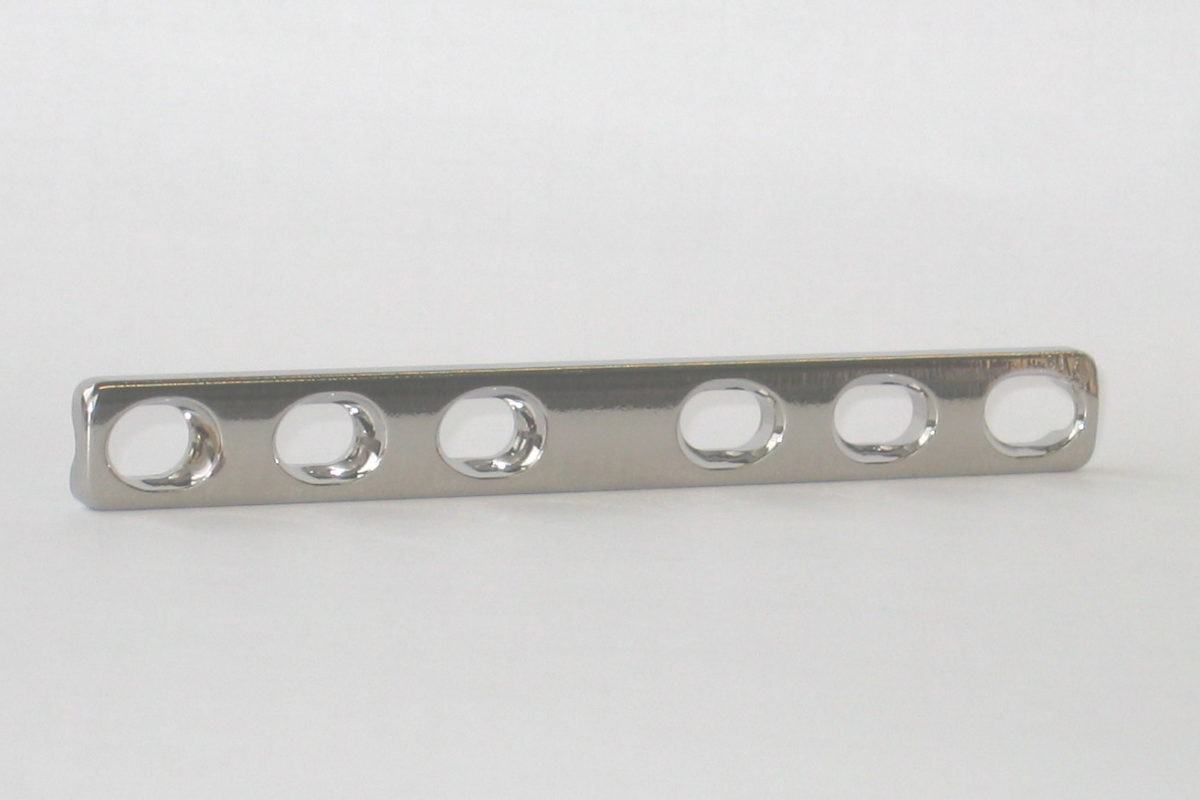

Typical applications

Processing plants for the chemical, pharmaceutical, food and drinks industries, processing plants for machinery and apparatus construction, medical instruments and implants, vehicle construction, architecture, mounting elements, sanitary engineering, domestic and kitchen appliances