Poligrat: Creating Added Value.

Pickling

Pickling

Pickling ensures the corrosion resistance of components made of stainless steel and thus considerably influences their service life and fitness for purpose.

Pickling achieves an intensive cleaning and activation of metal surfaces, through the removal of a thin layer of the material processed. The result is a metallically pure surface, free of oxides and contamination of other metals. Pickling attacks primarily the grain boundary of the metal structure and gives the surface a matt to satin gloss appearance.

Pickling can be carried out either chemically or electrolytically (anodically). Pickling chemicals usually contain mineral acids and an oxidation chemical as well as additives to improve the result and reduce pollutants.

Several methods are available for the pickling process:

- Immersion pickling for immersing, sprinkling or through-pumping

- Spray pickling involves spraying on an adhesive pickling paste onto free-standing areas

- Brush pickling for local treatment by painting the chemicals e.g. onto welding seams

Non-rusting steels, nickel-based alloys and titanium are usually pickled following processing, in order to create a good starting point for the further processing or creating an intact passive layer as a precondition for corrosion resistance.

Normal steel, copper materials and aluminium are pickled for cleaning purposes or pre-treatment before electropolishing, chemical deburring, polishing, anodizing or galvanizing.

Rinsing water and used pickling chemicals must be treated and disposed of in accordance with the legal regulations.

Stainless steel and nickel-based alloys

Chemical immersion pickling:

- POLINOX B with additives to prevent nitrous gases, nitrite and chromates

- POLINOX NF nitrate-free

- POLINOX UB (patented) free from mineral acids, environmentally friendly, can also be applied anodically

- POLINOX VA 100 (patented) free from nitrates, sulphates or phosphates. For all stainless steels, optionally with or without metal removal, can also be operated without waste water in a closed system.

Electrolytic immersion pickling (anodic):

- POLINOX AB

- POLINOX UB

Spray pickling:

- POLINOX FL Dispers

- POLINOX FL Aktiv

Brush pickling:

- POLINOX P Rapid

- POLINOX P Retard

Titanium and titanium alloys (immersion pickling)

- POLINOX TB 100

Carbon steel (immersion pickling)

- POLINOX BESTA (pickling inhibitor)

- POLINOX BESTA S (without hydrochloric acid, no hydrogen embrittlement)

Aluminium and aluminium alloys

- POLINOX AT 100

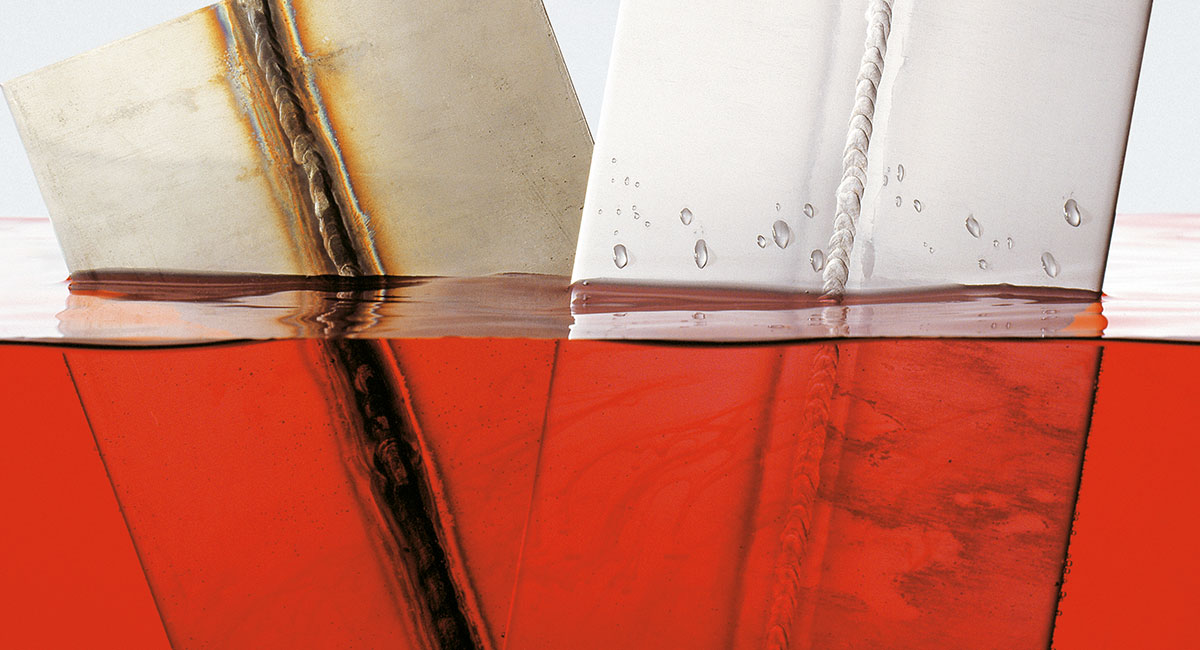

Chemical plant, pickled on site and passivated for improved corrosion resistance and metallic purity

Titanium sheet, untreated

Titanium sheet, pickled for improved corrosion resistance

Stainless steel fittings, pickled chemically and cleaned for improved corrosion resistance

CONVINCE YOURSELF!

With our experience and our procedures, we discover new potentials for you, to create more value. That’s why we work in partnership with you and are already developing answers to your questions of tomorrow. We look forward to showing you the opportunities and potential for your company – challenge us!

Poligrat:

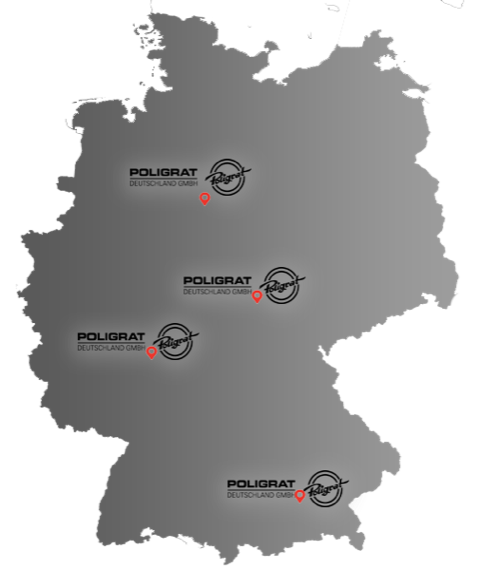

The POLIGRAT Group is the international market and technology leader in its core competence. That’s why we are represented in all relevant markets.

YOU CAN FIND ONE OF OUR PLANTS NEAR YOU:

POLIGRAT Deutschland GmbH

Valentin-Linhof-StraĂźe 19

81829 Munich

Germany

Tel: +49 (89) 42778-0

Fax: +49 (89) 42778-309

info@poligrat.de

www.poligrat.de

POLIGRAT Deutschland GmbH

Emil-PaĂźburg-StraĂźe 2

99310 Arnstadt

Germany

Tel: +49 (3628) 6197-0

Fax: +49 (3628)6197-77

ndl-ost@poligrat.de

www.poligrat.de

POLIGRAT Deutschland GmbH

Werner-von-Siemens-StraĂźe 2

Halle 5.5

64319 Pfungstadt

Germany

Tel: +49 (6157) 98632-0

Fax: +49 (6157) 98632-119

ndl-west@poligrat.de

www.poligrat.de

GUSTAV MORSCH GmbH

Utermöhlestraße 10

31135 Hildesheim

Germany

Tel: +49 (5121) 7671-0

Fax: +49 (5121) 7671-39

ndl-nord@poligrat.de

www.poligrat.de

POLIGRAT UK Limited

2 Holder Road

Aldershot

Hampshire GU 124 RH

Great Britain

Tel: +44 (1) 252 336337

Fax: +44 (1) 252 322791