CARBOCHEM C 600

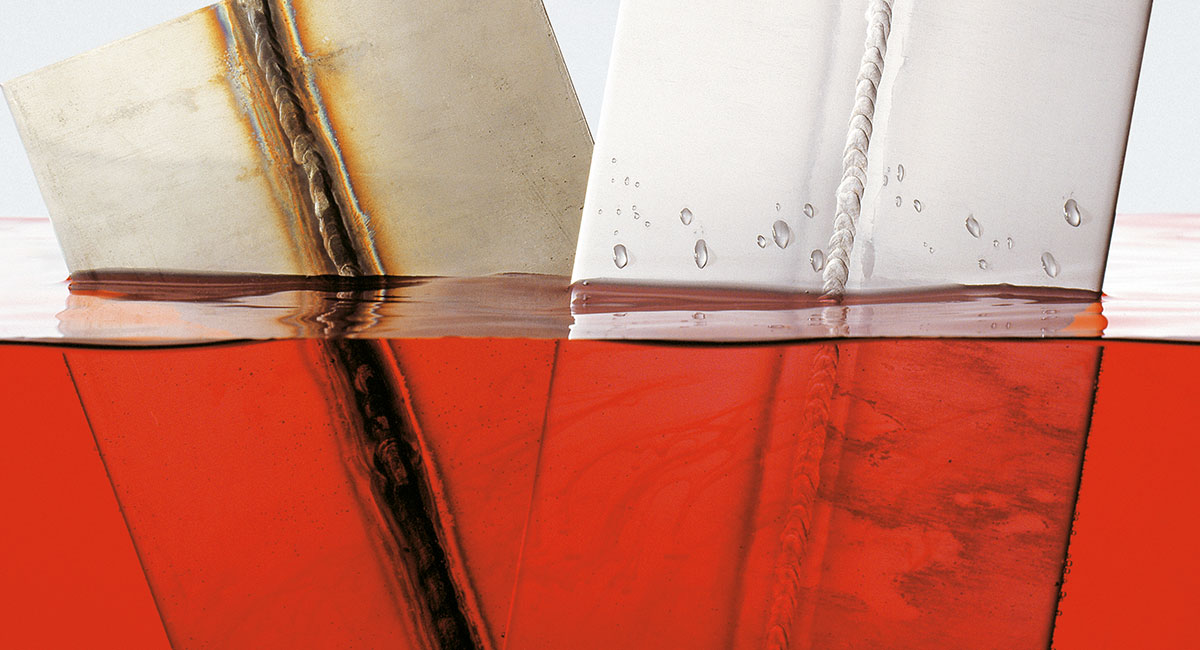

Chemisch Entgraten und Polieren von C-Stahl

You need help? Of course!

You have further questions concerning our chemicals and how to use them?

Please do not hesitate to contact us. You can contact the responsible person of the division Poligrat Chemistry by the following telephone number:

+49 (89) 42778- 450

CarboChem C 600 provides the possibility of fast and reliable deburring, de-flaking and smoothening at the entire surface of mild steel parts. Crack seeds and metallic sticking metal flakes will be removed, even they are located at the inside of the goods. The lifetime of mechanically high loaded parts, such like springs or pressurized tubes are increased significantly.

The high metal absorbing capacity (up to 70 g Fe/l) in combination with its high metal removal speed allows very short process times at minimized chemical consumption. The removal rate can be adjusted in the range from 0.5 – 5 μm/min.

CarboChem C 600 is an immersion process, although it can be applied in pump flow process too.

The parts can be processed either on jigs, in baskets or as bulk goods in rotary barrels.

Process sequence:

- Degreasing in hot alkaline

- Derusting/activation in POLINOX Besta S

- Smoothening and deburring in Carbochem C 600

- Temporary corrosion protection in CarboPassiv 6 or Dewatering Fluid

Smoothening and deburring are stable within the working range and nearly independent of the metal concentration. The loss of oxygen during production and short no working periods is minimized. Under normal working conditions the dosing of concentrate C 600 K is sufficient to compensate the consumption by the metal removal. Automatic dosing provides the most effective use of CarboChem C 600 keeping the metal concentration at its maximum limits.

The process bath is not to be classified as toxic up to a specific removal rate of 2.2 ÎĽm/min, due to the low concentration of HF. The high efficiency reduces the chemical consumption significantly, protects the environment and saves resources. CarboChem C 600 does not contain Ammonia compounds and can be handled in conventional neutralization waste water plants. The electrolyte and the rinse water from the process are acidic and contain the dissolved metal. They need to be treated and disposed of according to the statutory provisions and regulations.

Density: 1.00 – 1.10 g/ml

Application: dissolved

Working temperature: 20 – 30 °C

Process time: 2 – 15 min.

- best economical process

- rapid deburring

- low process temperature

- resource saving

Single-use canister 30kg (25.8 l)

C 600 K

IBC 1,000 l

C 600 K

Single-use canister 30kg (260 l)

C 600 SK

Barrel 200 l

C 600 SK

IBC 1,000 l

C 600 SK